The strength of a permanent magnet is determined by several factors. Here are some key factors that affect the strength of a permanent magnet:

1. Material composition: The choice of materials used in a permanent magnet greatly affects its strength. The most common materials used for permanent magnets are iron, nickel, cobalt, and their alloys. These materials have high magnetic permeability and retain their magnetization well. Additionally, rare-earth elements like neodymium and samarium are used to create extremely powerful magnets.

2. Magnetic domains: Inside a permanent magnet, there are microscopic regions called magnetic domains. Each domain consists of aligned magnetic moments of individual atoms. A strong magnet has a large number of well-aligned domains that add up to create a stronger overall magnetic field.

3. Magnetization process: The process used to magnetize a material affects the strength of the resulting magnet. During the magnetization process, an external magnetic field is applied, either in the form of a strong current passing through a coil or a powerful magnet. This aligns the magnetic domains, enhancing the overall magnetization and strength of the magnet.

4. Magnetic orientation and shape: The orientation and shape of a permanent magnet also impact its strength. A magnet with a unidirectional alignment of its magnetic domains, known as an anisotropic magnet, is generally stronger than one with a random domain orientation. Moreover, some magnet shapes, like the bar or disc shape, provide better magnetic field concentration and therefore higher strength.

5. Temperature: The strength of a permanent magnet is affected by temperature. At higher temperatures, the thermal energy disrupts the alignment of the magnetic domains, reducing the overall magnetization and weakening the magnetic field. Different magnet materials have different temperature tolerances, and some are better suited for high-temperature applications.

6. Magnetic circuit: The magnetic circuit in which a permanent magnet is placed can affect its strength. The circuit consists of the magnet, a magnetic conductor (e.g., steel), and an air gap. The choice of materials, geometry, and magnetic path within the circuit can optimize the efficiency and strength of the magnet's field.

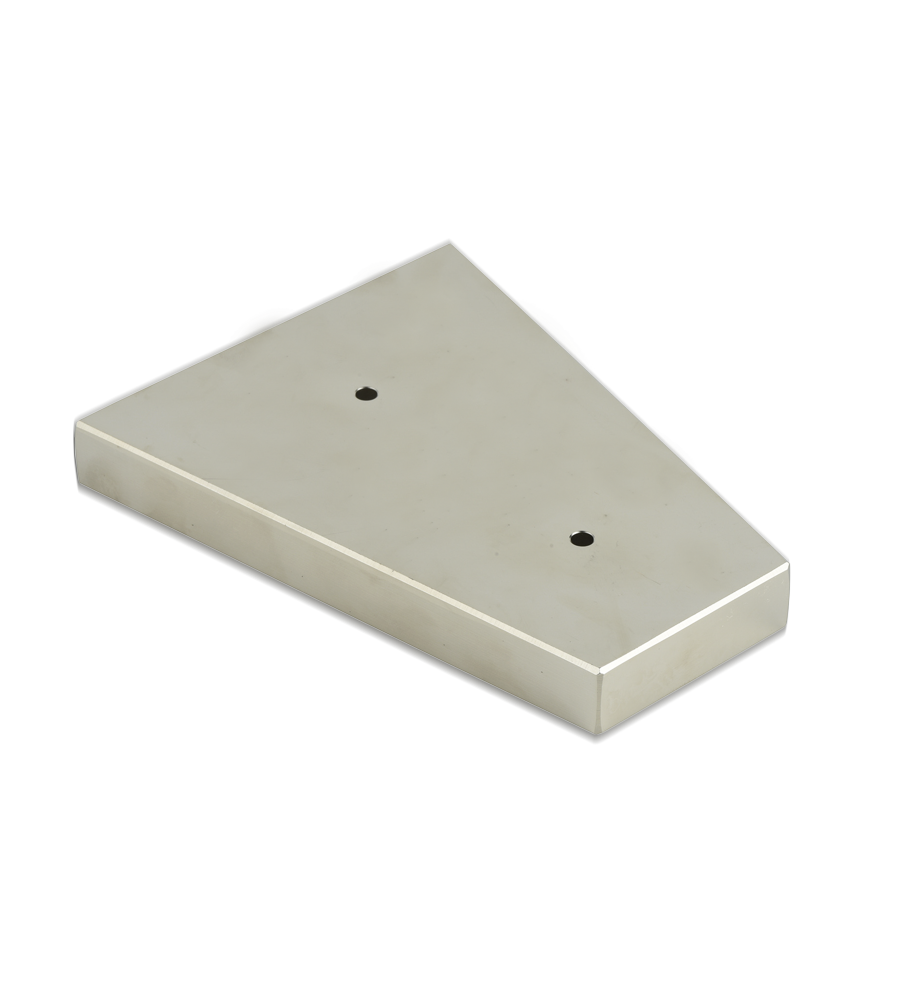

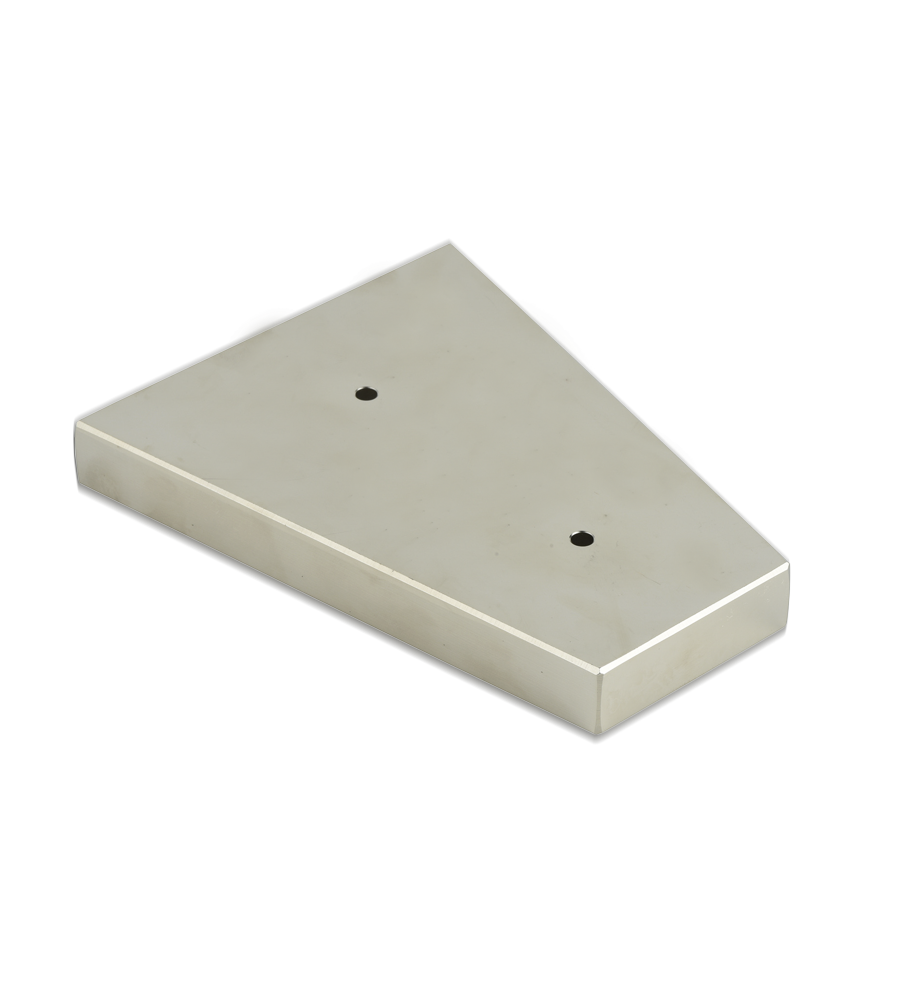

Permanent Neodymium Wind Generator Magnets

Permanent Neodymium Wind Generator Magnets

It is sintered neodymium magnet, it is a powder metallurgy technique.The smelted alloy is made into powder and pressed into a compact in a magnetic field. The compact is sintered in an inert gas or vacuum to achieve densification. In order to improve the coercivity of the magnet, an aging heat treatment is usually required.

Popular Grade: N33,N35,N38.N42,N45,N50,N52 N35SH/N38SH/N42SH N30UH/N35UH/N38UH/N40UG 35H/38H/40H/42H/45H/48H

Welcome to provide your drawing and specification to make your customized magnet.

中文简体

中文简体 English

English