The production and use of motor magnets can have various environmental considerations, including:

1.Resource extraction: The primary materials used in motor magnets, such as rare earth elements and metals, are often extracted from the earth using mining techniques that can have significant environmental impacts, such as habitat destruction, water pollution, and greenhouse gas emissions.

2.Energy consumption: The production of motor magnets requires significant amounts of energy, particularly during the refining and manufacturing processes. The energy used in the production and use of motor magnets contributes to greenhouse gas emissions and can also have impacts on local air quality.

3.Waste generation: The production of motor magnets generates waste products, such as mining tailings and industrial waste, which can have significant environmental impacts if not managed properly.

4.End-of-life disposal: When motor magnets reach the end of their lifespan, they need to be disposed of or recycled. Some materials used in motor magnets are hazardous and can pose risks to human health and the environment if not handled properly.

5.Recycling: Recycling motor magnets can help to reduce the environmental impacts of their production by reducing the need for new materials. However, recycling is not always straightforward, as motor magnets can be difficult to disassemble and the materials used in them may be difficult to separate.

6.Environmental regulations: There are various regulations at the local, national, and international levels that govern the production and use of motor magnets. These regulations aim to minimize environmental impacts and ensure that motor magnets are produced and used in a sustainable manner.

As a result of these environmental considerations, there is growing interest in developing more sustainable alternatives to motor magnets. This includes the development of alternative materials, such as high-performance plastics and ceramics, that can be used in motor applications. Additionally, efforts are underway to improve the recycling and reuse of existing motor magnets to minimize their environmental impact.

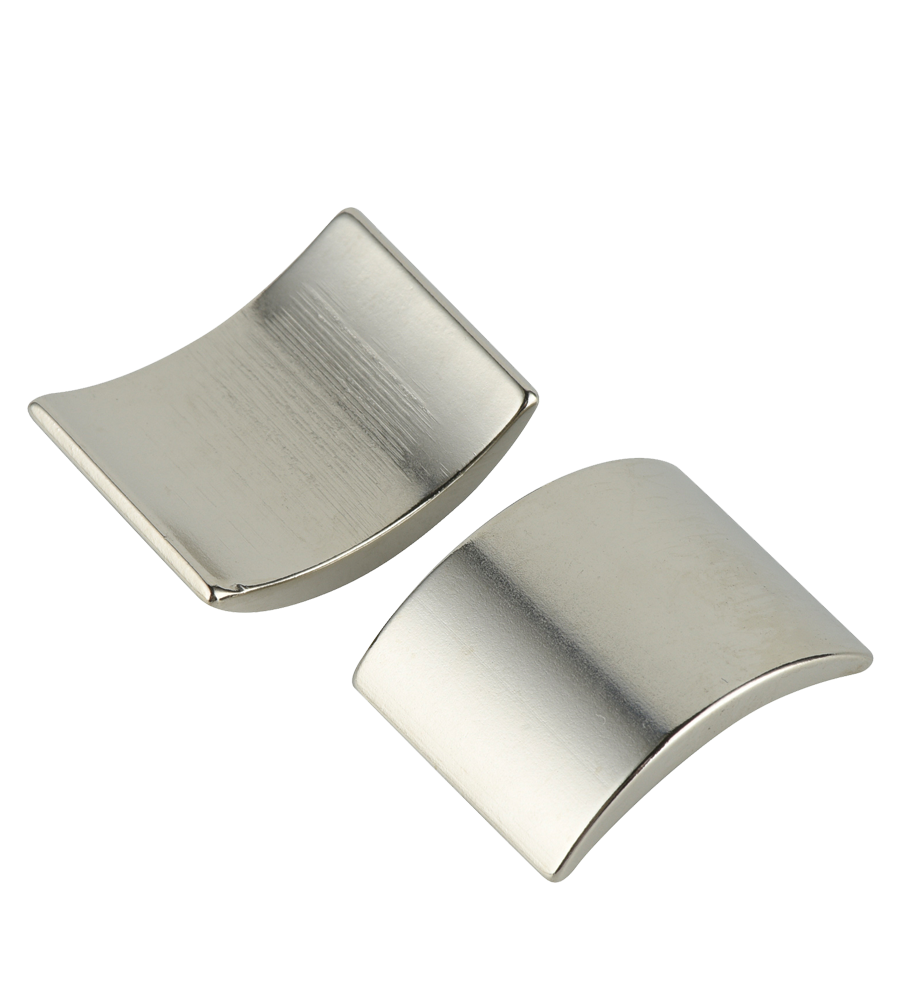

Servo motor magnet

Popular Grade: N33,N35,N38.N42,N45,N50,N52 N35SH/N38SH/N42SH N30UH/N35UH/N38UH/N40UG 35H/38H/40H/42H/45H/48H

Welcome to provide your drawing and specification to make your customized magnet.

中文简体

中文简体 English

English