NdFeB magnets, also known as Neodymium-Iron-Boron magnets, are distinct from other types of magnets in several ways. Here are some key differences:

1.Magnetic Strength: NdFeB magnets are known for their exceptional magnetic strength, which is significantly higher than other types of magnets, including ceramic (ferrite) magnets and AlNiCo (Aluminum-Nickel-Cobalt) magnets. They have the highest magnetic energy product, allowing them to generate strong magnetic fields.

2.Size and Weight: NdFeB magnets are much smaller and lighter compared to magnets with similar magnetic strength. This makes them highly desirable in applications where compactness and weight reduction are crucial factors.

3.Cost: NdFeB magnets tend to be more expensive than ceramic magnets and AlNiCo magnets. The high cost is primarily due to the scarcity and cost of neodymium, a rare earth element used in their composition.

4.Operating Temperature: NdFeB magnets have relatively lower maximum operating temperatures compared to ceramic magnets and AlNiCo magnets. They can begin to lose their magnetic properties at high temperatures, typically above 80°C (176°F), although specialized grades can withstand higher temperatures.

5.Coating and Protection: NdFeB magnets are prone to corrosion due to the iron content in their composition. They require protective coatings such as nickel, zinc, or epoxy to prevent oxidation and preserve their magnetic performance. Ceramic and AlNiCo magnets, on the other hand, are more corrosion-resistant.

6.Brittle Nature: NdFeB magnets are relatively more brittle compared to other magnets. They can chip or break if subjected to impact or high mechanical stress. Care should be taken during handling and assembly to avoid damage.

7.Versatility: NdFeB magnets offer a wide range of shapes, sizes, and grades, allowing for versatile applications. They are commonly used in areas such as electronics, automotive industries, medical equipment, and renewable energy systems.

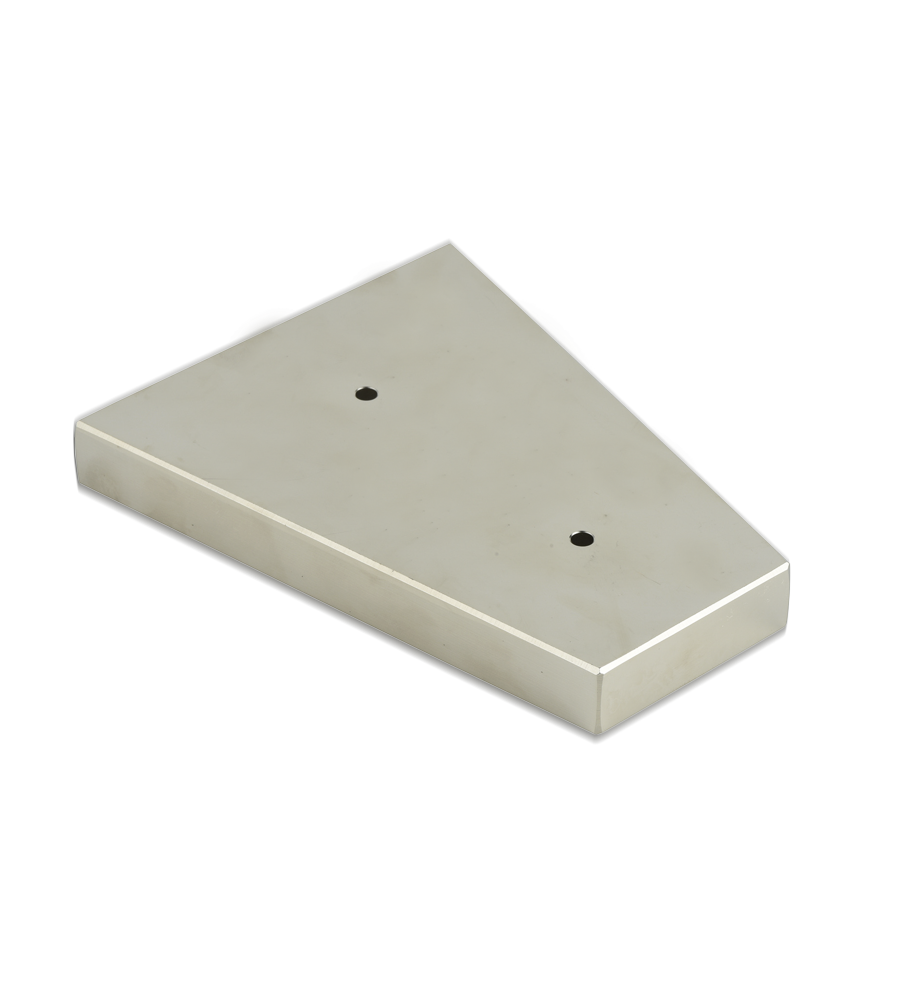

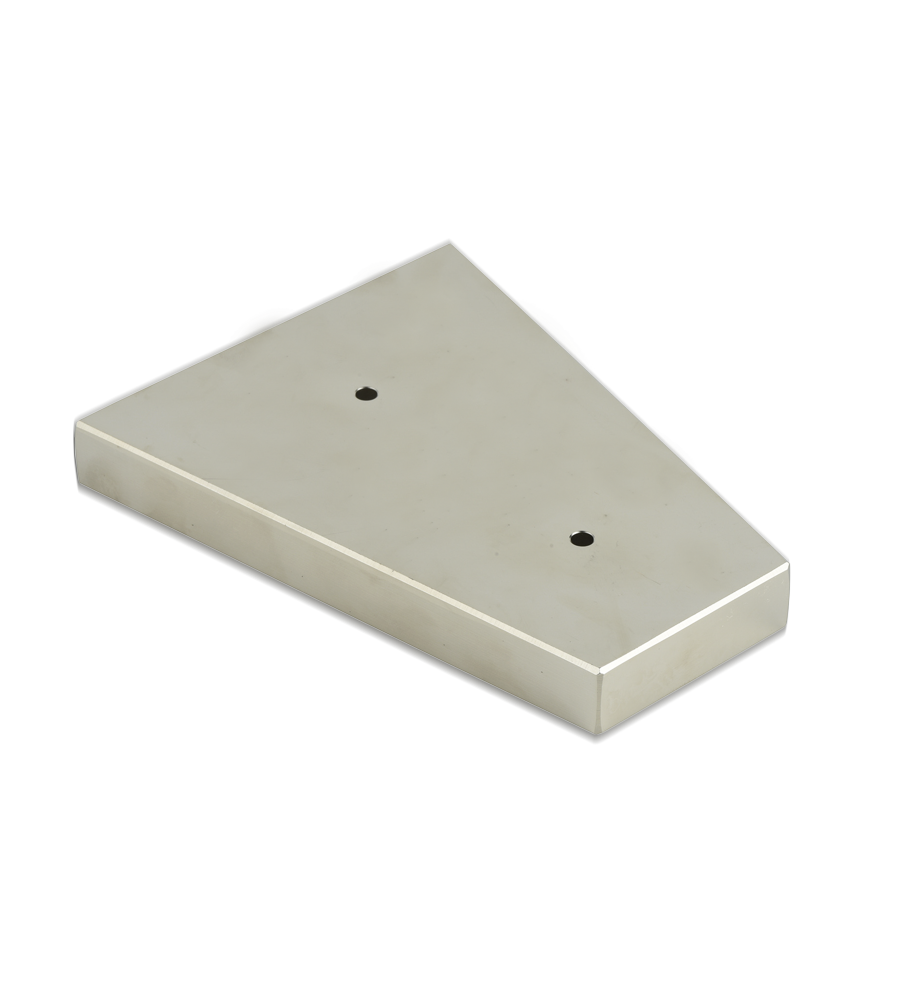

Permanent Neodymium Wind Generator Magnets

Permanent Neodymium Wind Generator Magnets

It is sintered neodymium magnet, it is a powder metallurgy technique.The smelted alloy is made into powder and pressed into a compact in a magnetic field. The compact is sintered in an inert gas or vacuum to achieve densification. In order to improve the coercivity of the magnet, an aging heat treatment is usually required.

Popular Grade: N33,N35,N38.N42,N45,N50,N52 N35SH/N38SH/N42SH N30UH/N35UH/N38UH/N40UG 35H/38H/40H/42H/45H/48H

Welcome to provide your drawing and specification to make your customized magnet.

中文简体

中文简体 English

English