Yes, neodymium magnets can be customized and shaped into specific designs for unique applications. Neodymium magnets are made from a combination of neodymium, iron, and boron, and they are known for their exceptionally strong magnetic properties.

Customization of neodymium magnets can involve various processes, such as cutting, drilling, grinding, and machining. These processes allow the magnets to be shaped into specific designs, sizes, and configurations to meet the requirements of different applications.

Here are some common ways neodymium magnets can be customized:

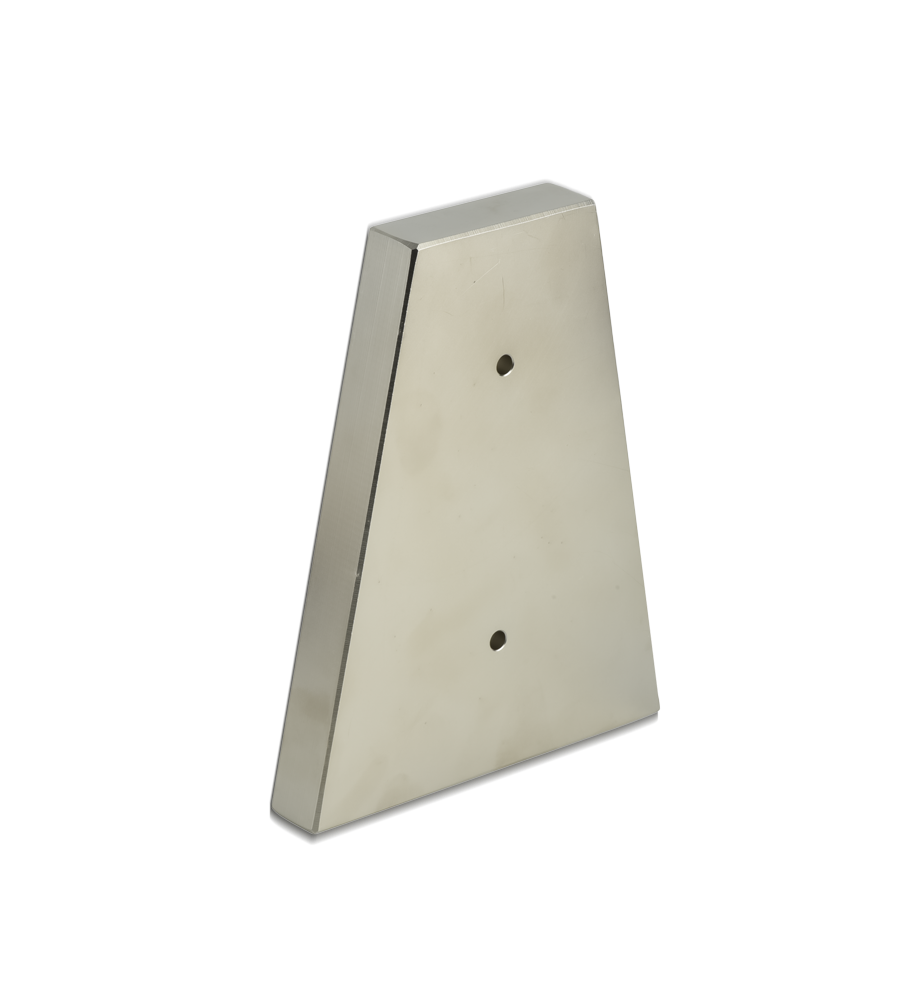

1.Cutting and shaping: Neodymium magnets can be cut and shaped using specialized tools, such as diamond saws, to create specific geometries. This allows for the creation of magnets with unique sizes and configurations.

2.Hole drilling: Neodymium magnets can be drilled to create holes or cavities for mounting purposes. This is particularly useful when magnets need to be attached to other components or structures.

3.Surface treatments: Neodymium magnets can undergo surface treatments to enhance their performance or protect them from corrosion. Common surface treatments include coating the magnets with nickel, zinc, or epoxy.

4.Magnet assemblies: Neodymium magnets can be combined with other materials, such as metal housings, to create magnet assemblies for specific applications. These assemblies can provide increased strength, protection, or specialized functionality.

It's important to note that customizing neodymium magnets requires expertise and specialized equipment due to their high magnetic strength and brittleness. Therefore, it is often recommended to work with experienced magnet manufacturers or suppliers who can provide the necessary customization services.

Wind turbine magnet

Popular Grade: N33,N35,N38.N42,N45,N50,N52 N35SH/N38SH/N42SH N30UH/N35UH/N38UH/N40UG 35H/38H/40H/42H/45H/48H

Welcome to provide your drawing and specification to make your customized magnet.

中文简体

中文简体 English

English